Knit Design: CAD Work Sketchbook

All images in this virtual sketchbook are from the SHIMA SEIKI SDS-ONE APEX software, used during a graduate-level knit design course at NC State University.

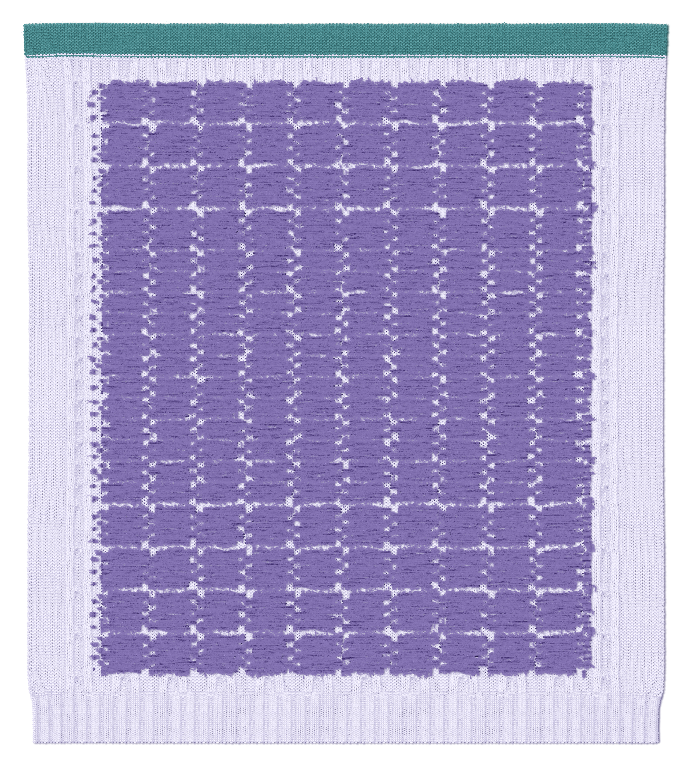

Simulation of the front view of a white, cotton cable knit with a purple, chenile, 2x2 basket inlay. Colors and yarns chosen for contrast.

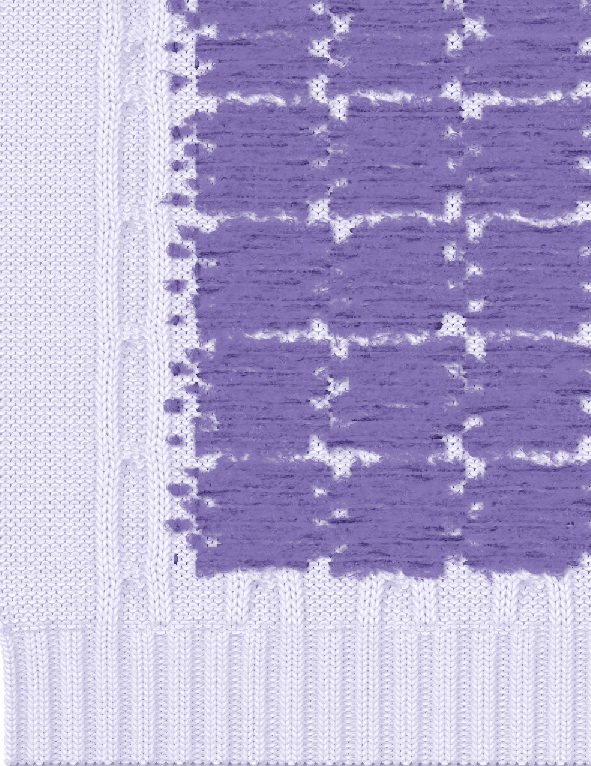

Zoomed-in simulation of the front view of a white, cotton cable knit with a purple, chenile, 2x2 basket inlay. Colors and yarns chosen for contrast.

Simulation of the back view of a white, cotton cable knit with a purple, chenile, 2x2 basket inlay. Colors and yarns chosen for contrast.

Zoomed-in simulation of the back view of a white, cotton cable knit with a purple, chenile, 2x2 basket inlay. Colors and yarns chosen for contrast.

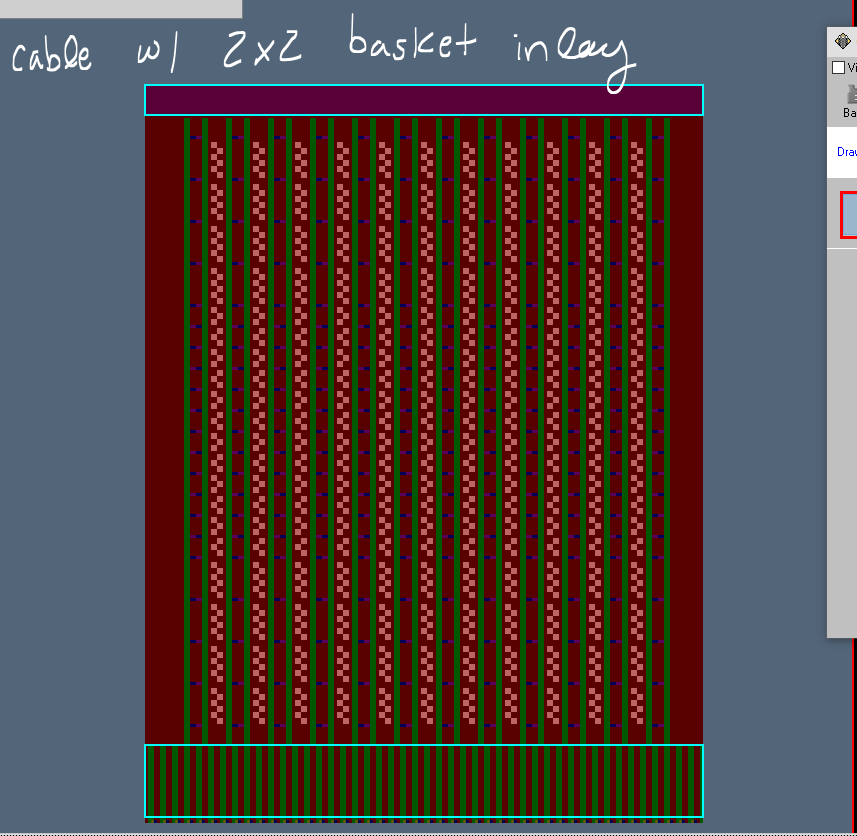

Captured from the APEX software- the design of a cable knit with a 2x2 basket inlay.

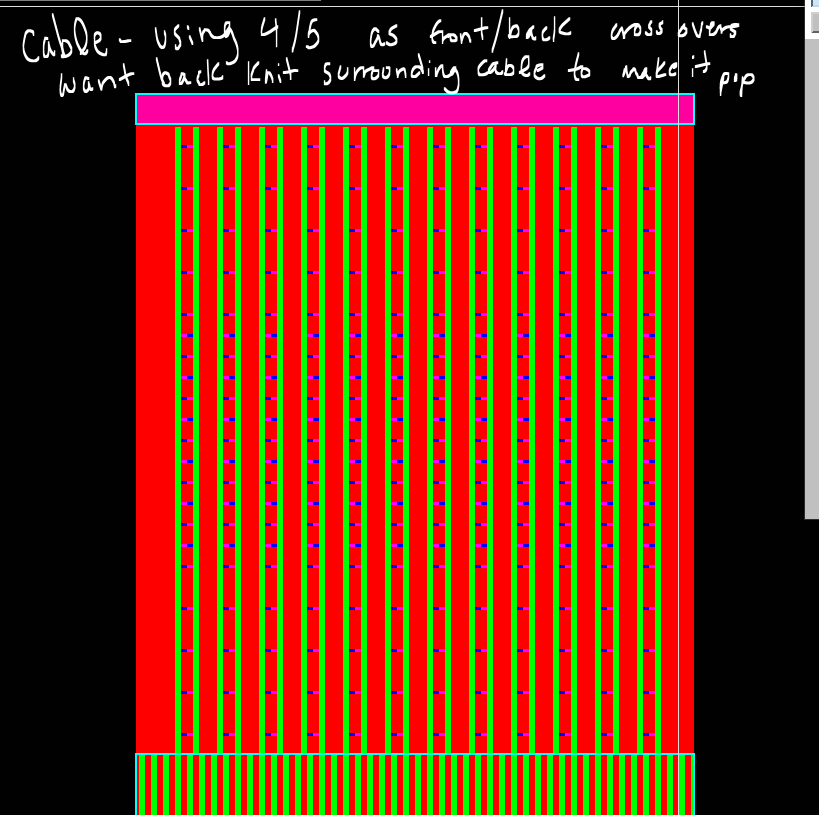

Captured from the APEX software- the design of a cable knit before adding a 2x2 basket inlay.

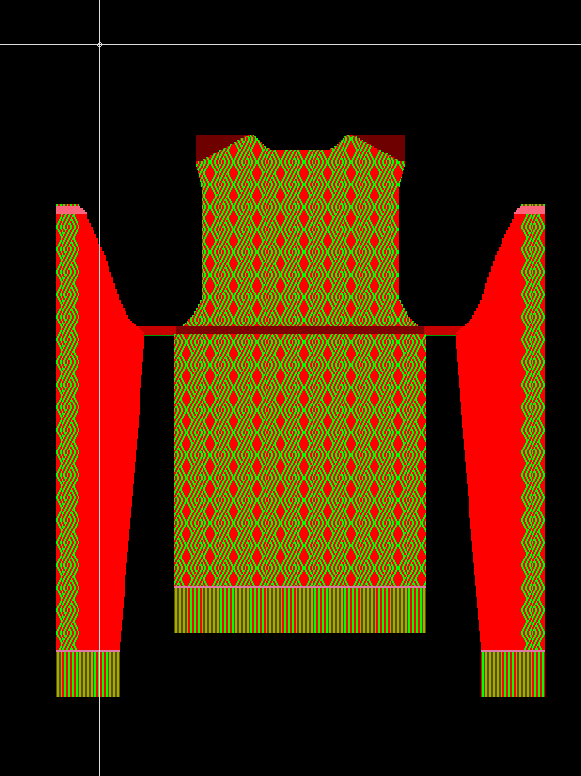

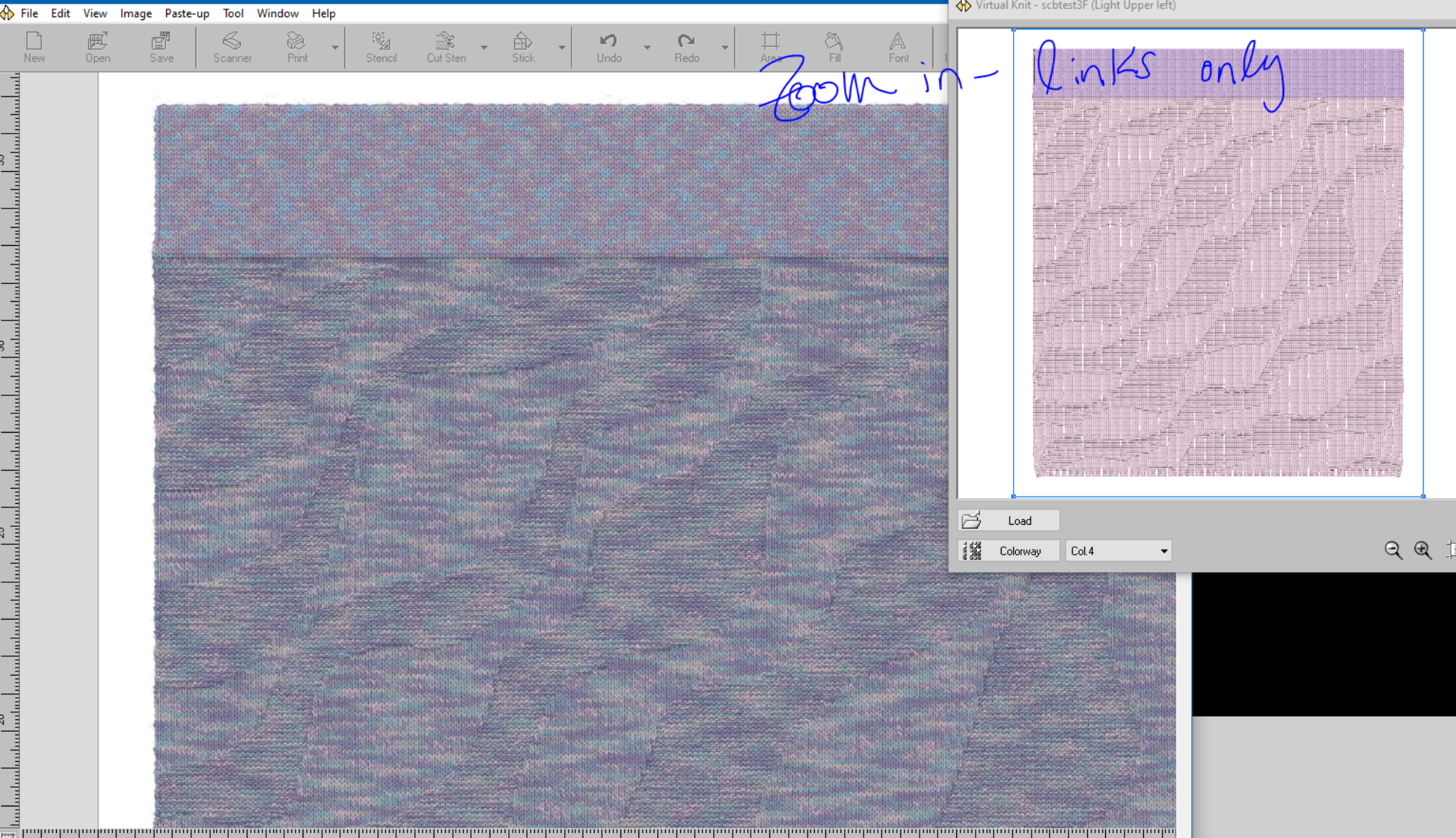

Adding links-links structures to the front of a v-neck, whole garment sweater to simulate a faux-cable knit. Intended to be knit on a MACH 2XS 15 gauge Whole Garment machine using a 50/2 cotton yarn on 2 ends.

Adding links-links structures to the back of a v-neck, whole garment sweater to simulate a faux-cable knit. Intended to be knit on a MACH 2XS 15 gauge Whole Garment machine using a 50/2 cotton yarn on 2 ends.

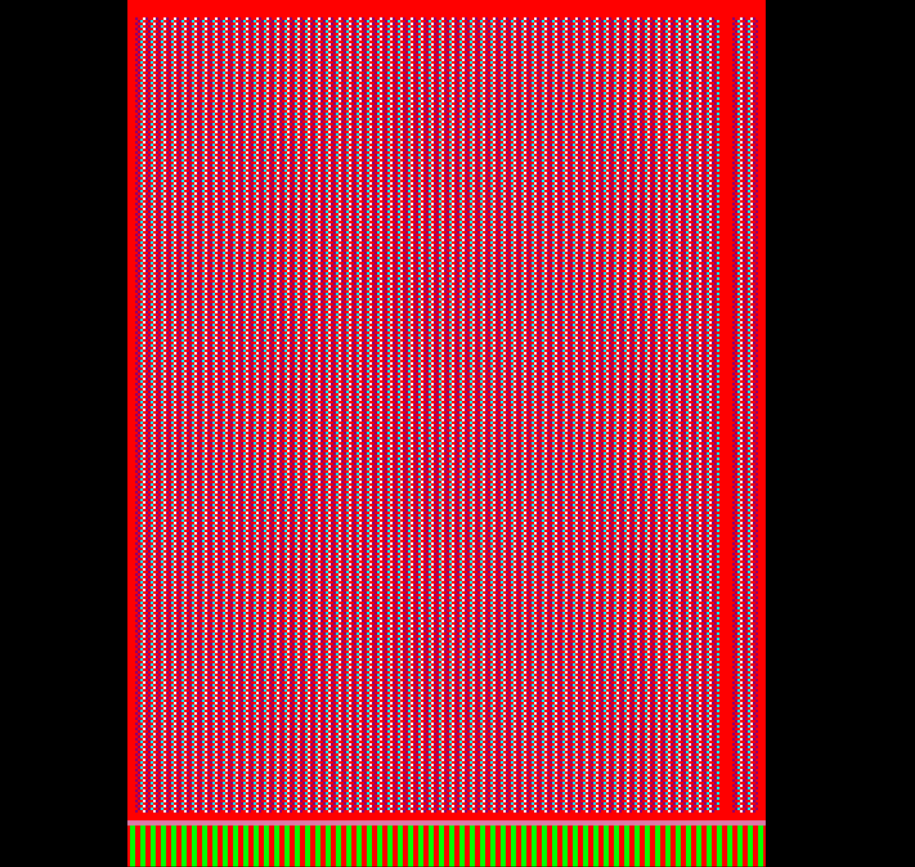

Test swatch of a full mesh panel, intended to be made on the MACH 2XS 8-gauge machine using a 10/1 yarn on 2 ends. End result was intended to be a very loose, open-knit with enough weight to be worn as a cardigan.

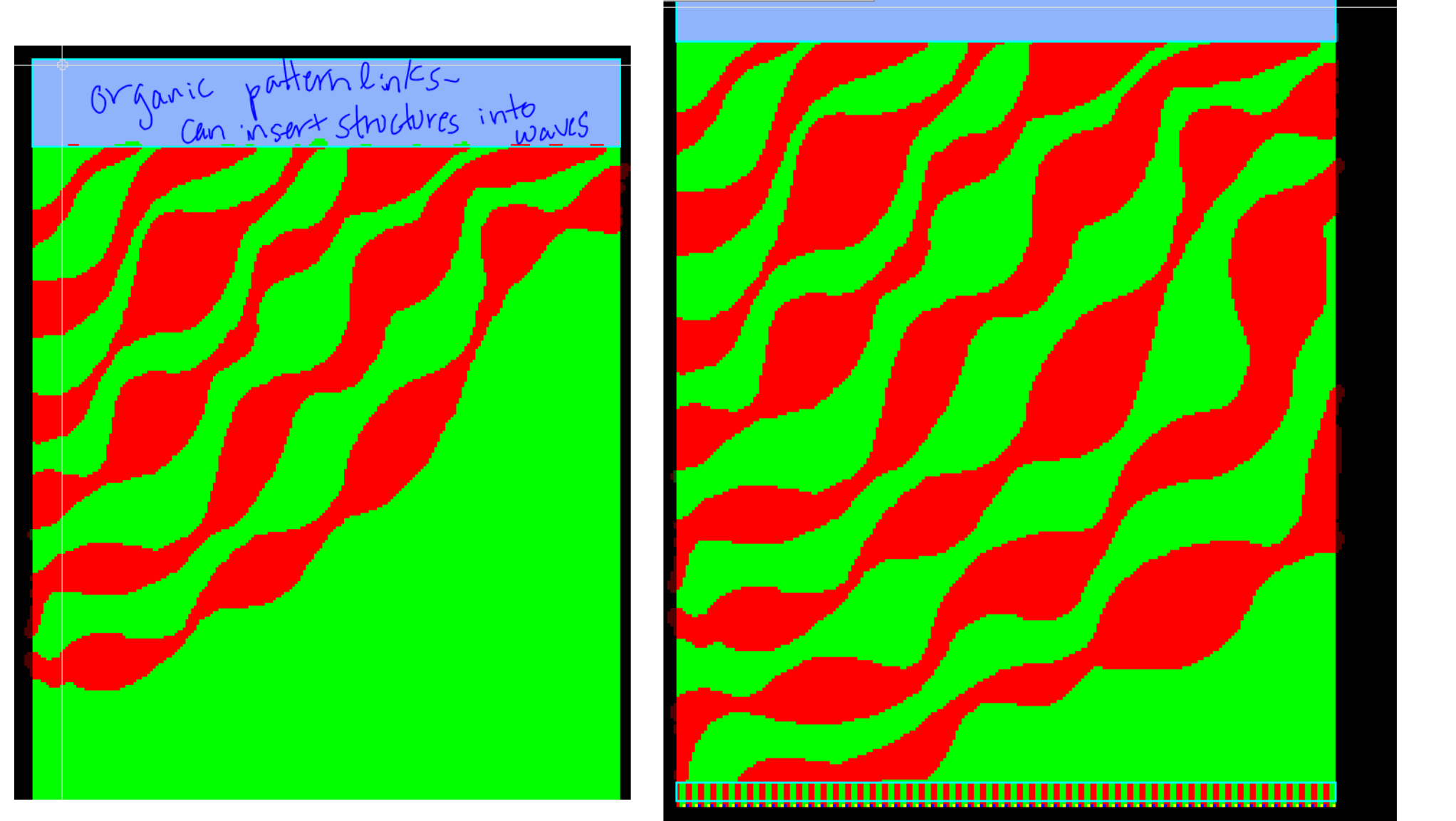

Creating a pattern of organic shapes on APEX software. Once initial shapes were created, additional knit structures were added in to create depth. Intended to be knit on SRY123LP 14-gauge machine. Originally created for my senior design collection, Behind Closed Doors. Final piece was instead created on Dubied hand-knitting machines. Click image to view more.

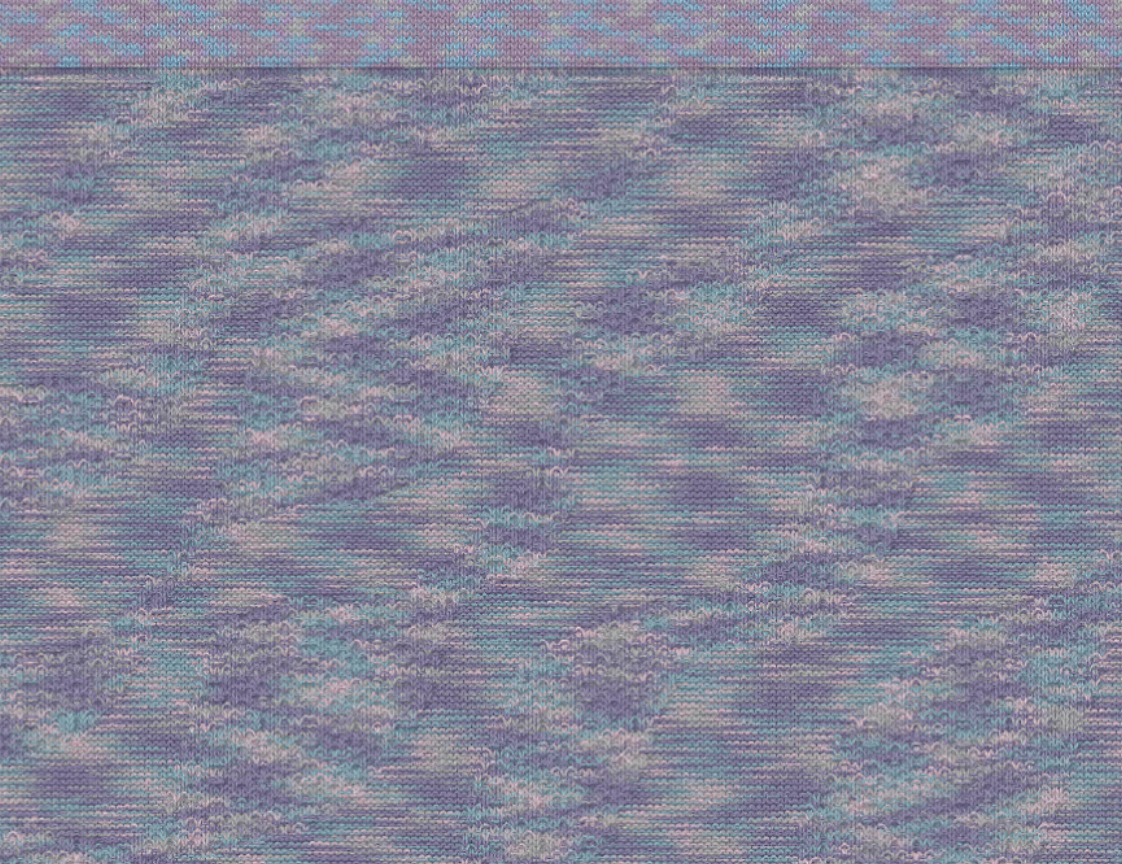

A snip of the simulation in the APEX software of the bubble pattern before filling organic shapes with additional knit structures. Simulated with a space-dyed, cotton yarn.

A zoomed-in snip of the simulation in the APEX software of the bubble pattern before filling organic shapes with additional knit structures. Simulated with a space-dyed, cotton yarn.

Intended to be knit on SRY123LP 14-gauge machine. Inside bubble shapes, cable cross-overs were added to give additional depth and texture to fabric. Unfortunately this created many errors in the software when simulating and would be unable to be knit on the machine.

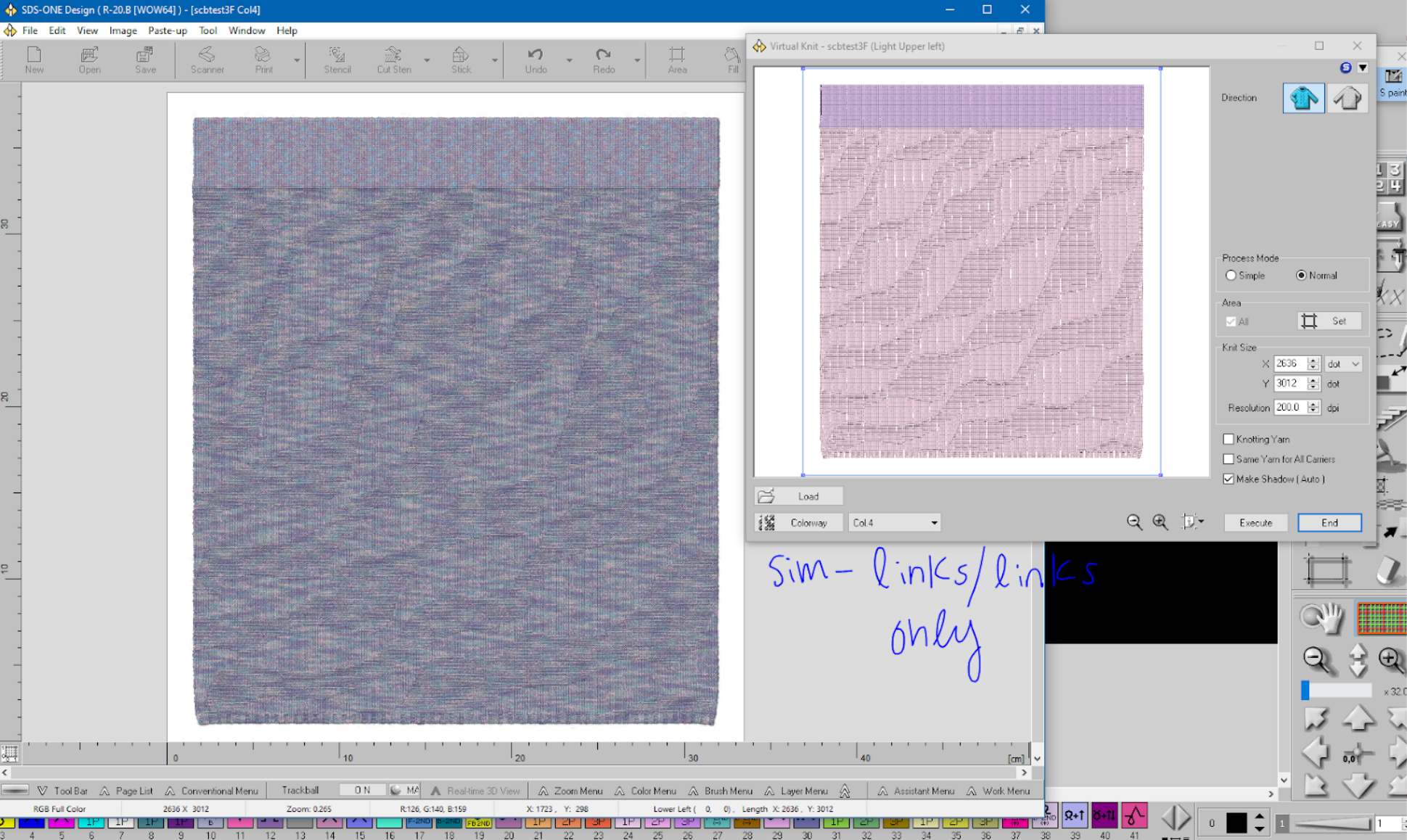

Intended to be knit on SRY123LP 14-gauge machine. Inside bubble shapes, I added patterns of links-links structures using the base pattern repeat tool to give the fabric additional texture.

A zoomed-in image of the simulation of the previous pattern on the APEX software, simulated using a space-dyed cotton yarn. Final yarn was intended to be a space-dyed yarn.

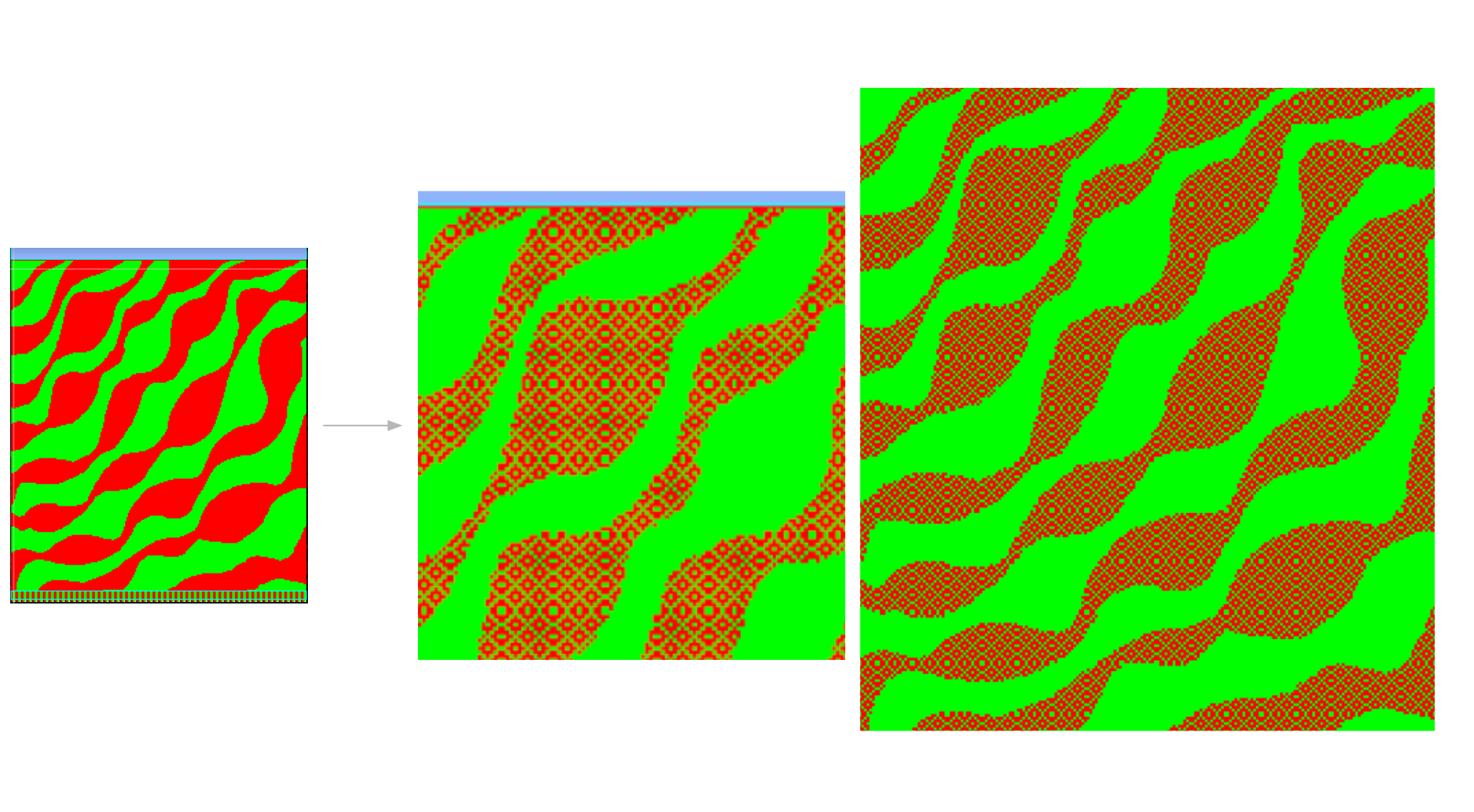

Another image of the simulation of the previous pattern on the APEX software, simulated using a space-dyed cotton yarn. Final yarn was intended to be a space-dyed yarn. This image shows the full 10x10 pattern as well as a zoomed-in portion to convey the texture given by the links-links structures.